A casual observer would be right to note that there are literally thousands of miles between the operation of satellites in space and sensors for automobiles or cameras here on terra firma. However, Wall Street Journal technology writer Christopher Mims recently highlighted the real-time, critical connection between the two in his column on nanosatellites.

According to Mims, companies are betting on these nanosatellites as the future of connectivity that will help enable the ongoing evolution of the Internet of Things (IoT). From tracking penguins in Antarctica to monitoring remote wind farms, these nanosatellites connect to Low Power, Wide Area networking protocols on the ground called LoRaWAN to deliver pinpoint precision for sensors anywhere on the planet.

But for IoT – and its fast-growing cousin the Industrial Internet of Things (IIoT) – the issue of connectivity is more than just tapping into the web via cellular networks. It involves a layered network of communications at multiple levels that enables the new and untold applications being dreamed up as part of these exciting fields.

For companies that want to play in IIoT, the stakes are high so it’s important to have a deep understanding of connectivity demands before committing budget or resources to hardware design. The team at Chariot Solutions has seen brilliant applications like water leak detectors that grew quickly because of smart planning, and then great ideas that simply floundered because of gaps in design or on the team.

Here are five basic steps to keep in mind when designing an IIoT project.

1. Visualize the Project

More than list-making refrigerators or web-enabled thermostats, the growing field of IIoT has companies thinking bigger and innovating in ways thought impossible before. But while the sky may no longer be the literal limit, initiating or maintaining a reliable connection is.

The first thing teams must do is understand their project goals and its related challenges. Engage business, hardware, and software stakeholders in this discussion to ensure alignment before the start of work. Properly framing the project, detailing needs and resources, and designing for your environment from day one will save a lot of time and budget in the long run.

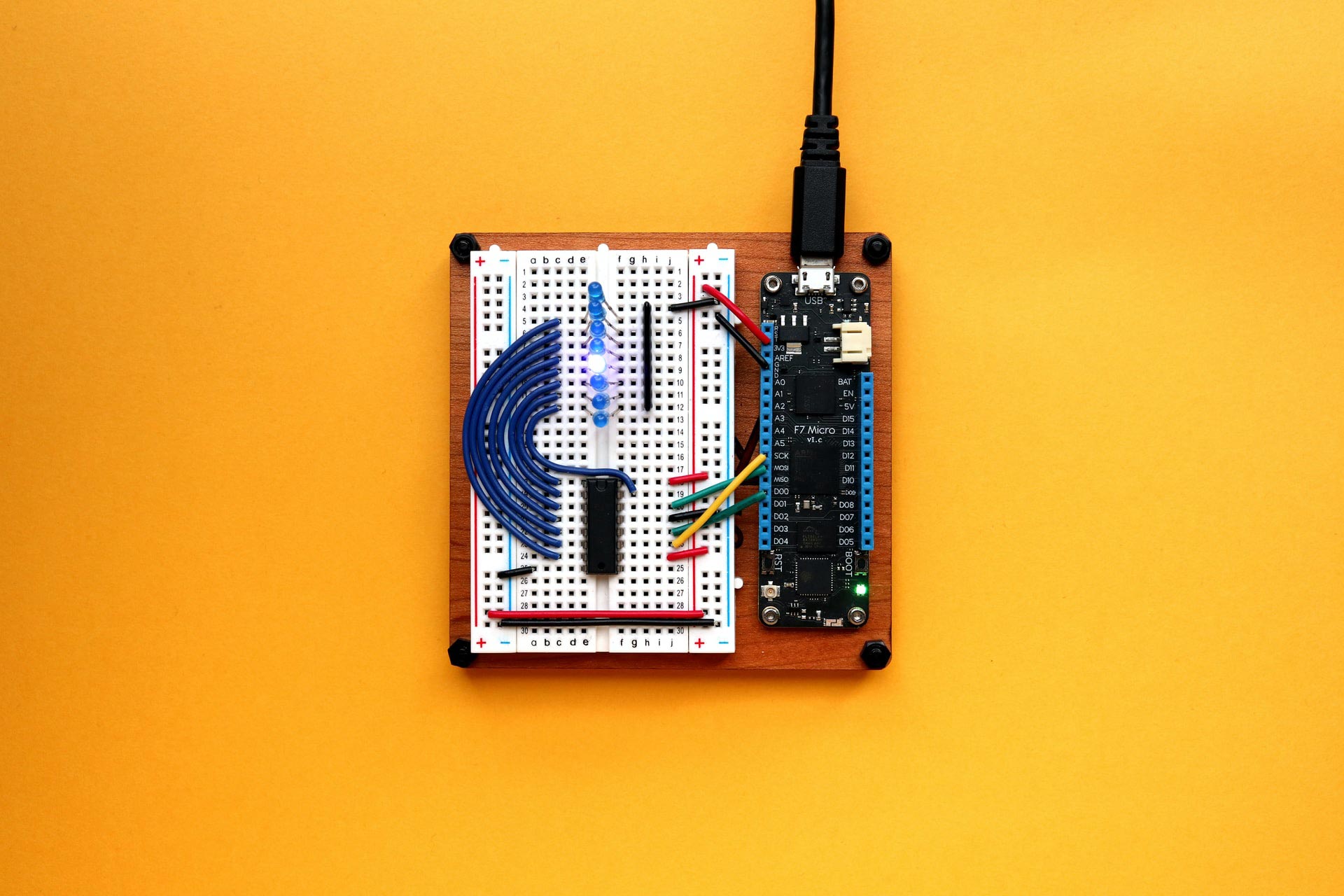

2. Integrated Sensor Design

The role of sensors in IIoT is both to capture data and then transmit it. This involves a complex relationship between hardware, firmware, software, and connectivity. Plus, the larger network-level applications of IIoT place even bigger demands on the connectivity of remote sensors.

Teams must work through all aspects of how to gather this data, broadcast it out, and receive firmware updates – all through an easy-to-establish connection. Each of these four aspects of a sensor must be well-designed and integrated. One point of failure can brick the entire sensor.

3. Ensure Connectivity

The physical components connecting a sensor to a network is only one aspect of connectivity. The other is the unique nature of your network.

IoT/IIoT connectivity is a term defining connection between all the points in the ecosystem, including sensors, gateways, routers, applications, platforms, and more. It often refers to different types of network solutions based on their power usage, range, and bandwidth consumption.

Importantly, cellular connectivity is not available to all sensors everywhere. For example, Chariot Solutions helped Canary Compliance connect its underground gas tank sensors to a mobile device above-ground. A cellular connection was not possible for this information handoff, so the team had to design a custom connection path.

Understanding all of the parts of the journey for IIoT to work is important for any company planning a project.

4. Hardware vs. Software Engineers

Engineers are not interchangeable parts of a design team. Hardware, firmware, and software designs demand specific skill sets and capabilities. Overlooking this basic delineation can have dire consequences for your project.

Recently, Chariot was approached by a company seeking help to understand why the firmware they had built for their sensor was not working properly. Our team determined that the firmware was designed without an understanding of how the information on the sensor could be unlocked. This lack of visualization and an assumption on the type of engineering required led to remediation to get the project back on track, causing significant time and cost overruns for the company.

Hardware engineers possess different skills than your software engineers. Understand their roles and how to help them collaborate.

5. Testing Plan

Hardware and software solutions are always bug-free once they enter production. And then we woke up from that dream! Testing IoT is challenging just like testing other complex systems.

Testing plans will need to be drawn up for the hardware, for the software, and the ways in which the hardware and software integrations. Sometimes the hardware is not available yet, so you need to build a mockup for the hardware and/or software. Taking the time to test the product won’t eliminate every bug, but it should create a smoother user experience.